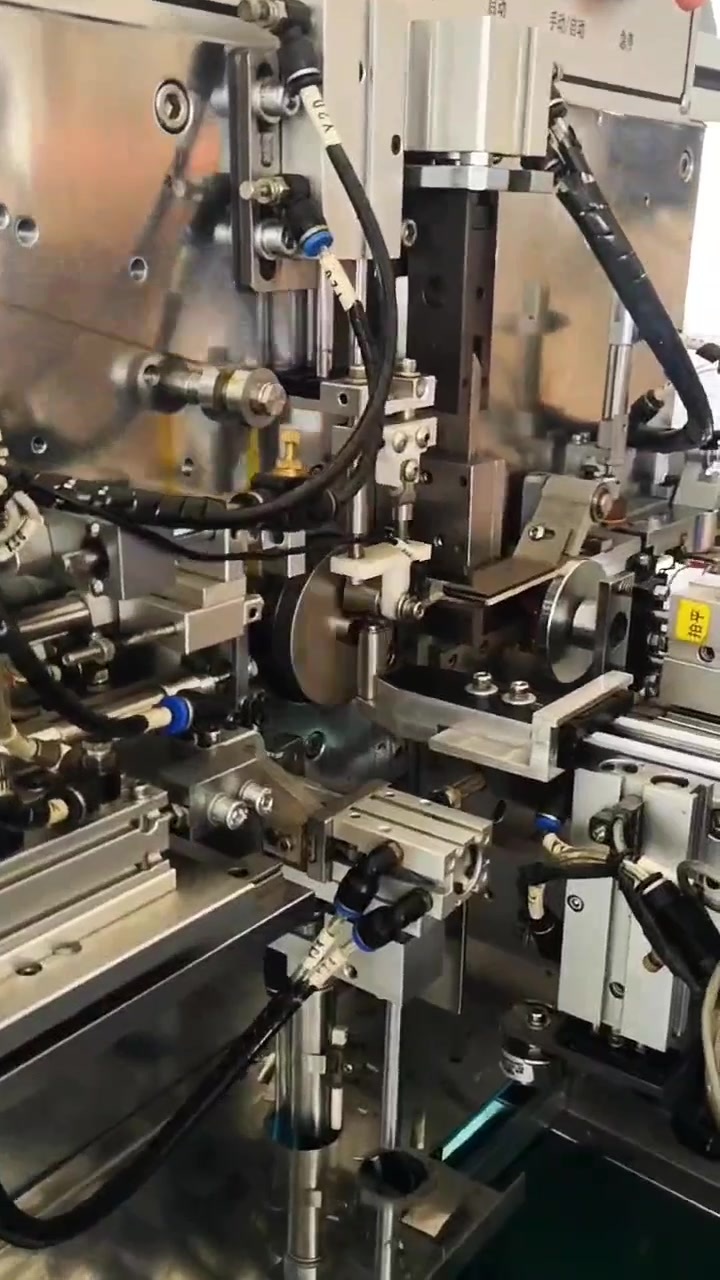

Fully automatic winding machine

Adopting a single station needle winding method effectively ensures the consistency of the battery cells. The entire device is easy to adjust.

Winding Machine

winding

machine

automatic

fully

Winding machine

tension

mechanism

Classifications:

Winding Machine

- Product Description

- Equipment Parameter

-

- Commodity name: Fully automatic winding machine

Adopting a single station needle winding method effectively ensures the consistency of the battery cells. The entire device is easy to adjust.

1. Adopting a single station needle winding method effectively ensures the consistency of the battery cells. The entire device is easy to adjust.

2. The positive and negative pole pieces are fed into the winding process using a one-way wheel compression method. This feeding method effectively ensures the feeding position of the pole pieces and the position of the pole ears, and eliminates the traditional positive and negative pole piece servo feeding mechanism, thereby improving the efficiency of the equipment.

3. The diaphragm and pole piece are both controlled by a low friction cylinder tension control method, and their tension is controlled by a proportional valve. Different tensions can be set at different times.

4. The winding needle is a bidirectional insertion type, and both winding needles are actively subjected to force during the winding process.

5. The positive and negative electrode plates adopt a precise correction mechanism to ensure the alignment of the plates, reducing the occurrence of short circuits caused by human operation during the winding process.

6. The positive and negative electrodes are cut by a white steel cutter, and the battery cells are wound and wrapped around the diaphragm.

7. The positive and negative electrode plates are equipped with dust removal devices, using two wheel hair wheels that are driven by a motor to rotate and suck out the dust on the electrode plates. This structure reduces the cross contamination of dust. In the past, when using a brush to vacuum, the brush could not rotate, so the dust on the previous electrode plate was often transferred to the next electrode plate.

8. The positive and negative pole pieces are equipped with a connecting device, which greatly saves the time of connecting the pole pieces when replacing them, improves the accuracy of pole piece docking, and reduces the waste caused by replacing the pole pieces by 8.Equipment appearance dimensions and working environment:

1. Dimensions: 2400mm (length) * 1900mm (height) * 1200mm (width);

2. Weight approximately 1200Kg;

3. Speed, pole length 500m, speed of 7-9 pcs/min;

4. The product qualification rate is 99% (excluding electrode defects and replacement materials);

5. Equipment utilization rate of over 90M;

6. Power supply AC220V 50HZ;

7. Power 3.0K4,

8. Air pressure 0.4-0 6lpa;

9. Environmental temperature: 0'C-38 '℃;

10. Coloring computer white (can be made according to customer requirements);

11. No corrosive gases, liquids, or explosive substances. Equipment appearance dimensions and working environment:

Video relacionado

Related Products

Fully automatic winding machine

Message to Us