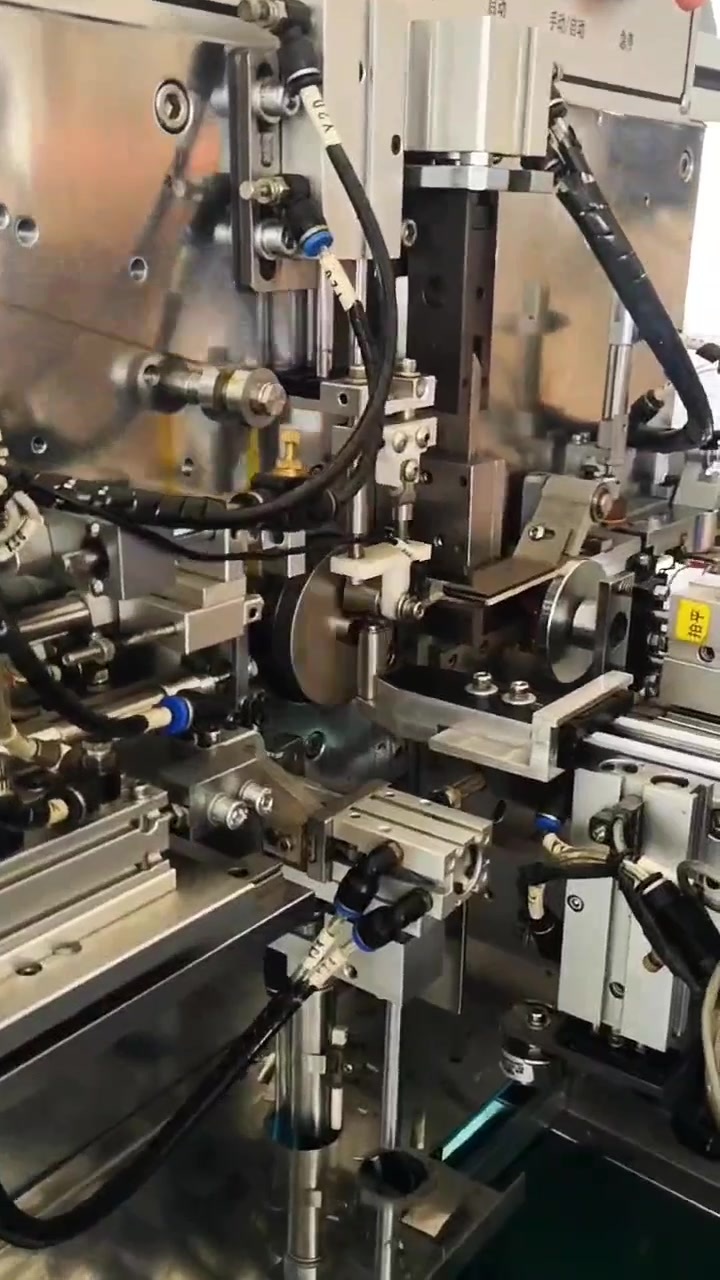

Nickel hydrogen battery cell winding machine

This machine is mainly suitable for winding round nickel hydrogen nickel zinc nickel cadmium battery cells.

Winding Machine

battery

tension

winding

diaphragm

Winding machine

polarizer

Classifications:

Winding Machine

- Product Description

- Equipment Parameter

-

- Commodity name: Nickel hydrogen battery cell winding machine

This machine is mainly suitable for winding round nickel hydrogen nickel zinc nickel cadmium battery cells.

1. This machine is mainly suitable for winding round nickel hydrogen nickel zinc nickel cadmium battery cells.

2. Manual single piece polarizer, automatic winding, automatic transposition, automatic tape termination and cutting, automatic cutting.

3. The diaphragm is continuous, and the diaphragm tension can be adjusted as needed, controlled by imported precision regulating valves.

4. The tension of the polarizer can be consistent with the tension of the diaphragm during the winding process. The clamping tension is controlled by a digital imported precision proportional valve, and the tension is set digitally with an adjustment range of (0Nm-10N. m). During operation, the tension size is automatically adjusted according to the set speed, number of turns, and needle width, ensuring good consistency of the outer diameter size of the wound battery cells.

5. The width of the polarizer guide plate can be adjusted to fit different types of polarizer widths, with high dimensional accuracy, wear resistance, and smoothness.

6. This device uses horizontal adhesive, and the length and width of the adhesive can be adjusted to easily ensure the appearance and dimensional quality of the battery cells.

7. The needle can be smoothly pulled out without affecting the neatness of the already coiled core, and without scratching the diaphragm or causing the core to spiral.

8. Suitable for winding battery cells with specifications ranging from 18 to 30

9. The needle change is convenient and takes no more than 10 minutes per payment.

10. Diaphragm continuous feeding method, PLC and precision potentiometer constant tension control, pressure sensor detection, uniform force distribution during battery cell winding process.

-

Material Science Length of material (mm) The width of the material Thickness of material (mm) Maximum diameter (mm) internal diameter(mm) Range of dimensions Size range tolerance Size range tolerance Positive electrode sheet 280-600

30-89

0.2 0.1–0.28 5 -------- -------- Negative electrode sheet 280-600 30-89 0.2 0.1–0.28 5 -------- -------- the diaphragm Roll material 31-90 0.2 0.016–0.045 - 300 76 Terminate the tape 10-30 10~40 0.2 0.1–0.35 - 300 76

Video relacionado

Related Products

Fully automatic winding machine

Message to Us