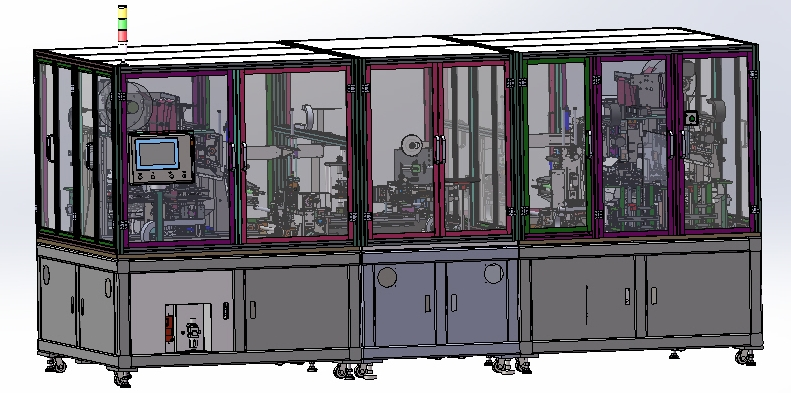

Fully automatic dual station laminating machine

This device is mainly used for Z-shaped stacking of square lithium-ion power battery cells.

Lamination Machine

dual

machine

station

laminating

automatic

mechanism

function

fully

polarizer

tension

Classifications:

Lamination Machine

- Product Description

- Equipment Parameter

-

- Commodity name: Fully automatic dual station laminating machine

This device is mainly used for Z-shaped stacking of square lithium-ion power battery cells.

1. This device is mainly used for Z-shaped stacking of square lithium-ion power battery cells.

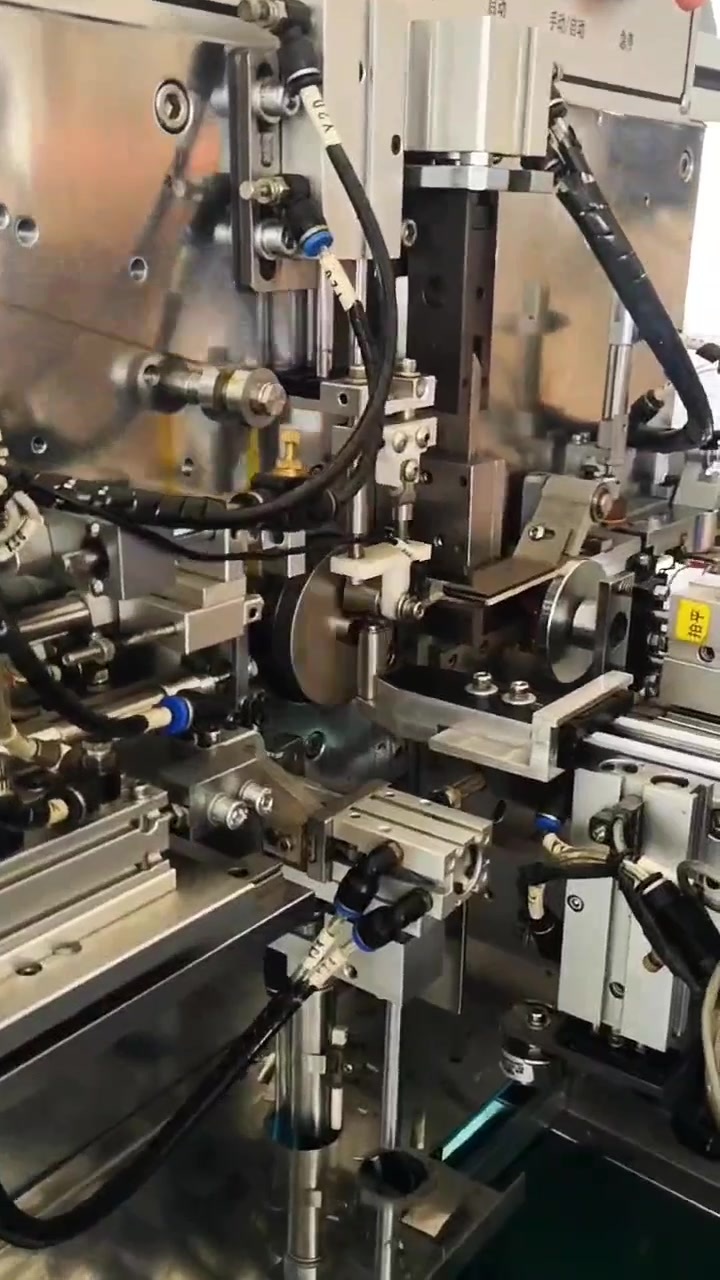

2. The diaphragm is actively unrolled by a motor, and after passing through a tension mechanism and a correction mechanism, it is introduced into a laminating table. The laminating table drives the diaphragm to move back and forth left and right to place the polarizer.

3. Four sets of robotic suction cup mechanisms are used to remove the positive and negative pole pieces from the material box, and after precise positioning, they are stacked on the loading platform for lamination.

4. There are eight sets of cross action claw mechanisms on the laminating table to press the pole pieces.

5. After the lamination is completed, the battery cells are transferred to the tail winding and gluing station through the battery cell transfer mechanism, and the tail winding, diaphragm cutting, and gluing are automatically performed; Automatic output of battery cells.Equipment features:

1. Double station stacking, fast speed, high production capacity;

2. Suitable for the production of large power battery cells;

3. The automatic correction function of the diaphragm ensures the accuracy of folding alignment;

4. Automatic tail winding function, adjustable tail winding length;

5. The automatic adhesive function can meet the four side adhesive function;

6. The automatic cutting function adopts an automatic stacking receiving method, which can collect multiple battery cells simultaneously.

7. Polar processing: Ultrasonic detection for missing or multiple pieces, corner detection for polar pieces, ear detection for polar pieces;

8. Dust treatment: The material box structure and secondary positioning structure are equipped with dust removal devices, and the positive and negative poles are isolated by organic glass plates to prevent dust cross infection. The main unit is equipped with an aluminum alloy protective cover;

Overall dimensions: (approximately) length: 3500mm; Width: 1700mm; Height: 1900mm

-

Project Technical specifications External dimensions Length 3500mm x Width 1700mm x Height 1900mm Equipment weight About 3000Kg Supply voltage AC380V 50/60Hz three-phase five wire Rated power 6kw Compressed air 5kgf-7kgf/c ㎡ (0.5Mpa-0.7Mpa) dry, anhydrous Gas consumption 250L/min Polar specifications Length 100-250mm, width 80-200mm Extreme ear specifications Length ≤ 30mm Cell thickness 4~25mm Stacking speed 0.5-0.6 seconds/piece/dual station End of roll time 10-15 seconds Pole alignment accuracy +/-0.3mm Diaphragm alignment accuracy +/-0.3mm (excluding tail end diaphragm) Diaphragm specifications Thickness Φ 15-50 μ m, inner diameter Φ 76mm, maximum outer diameter Φ 300mm Tape specifications Degree 100-200 μ m, width 10-20mm, inner diameter Φ 76mm, maximum outer diameter Φ 150mm

Video relacionado

Related Products

Fully automatic winding machine

Message to Us