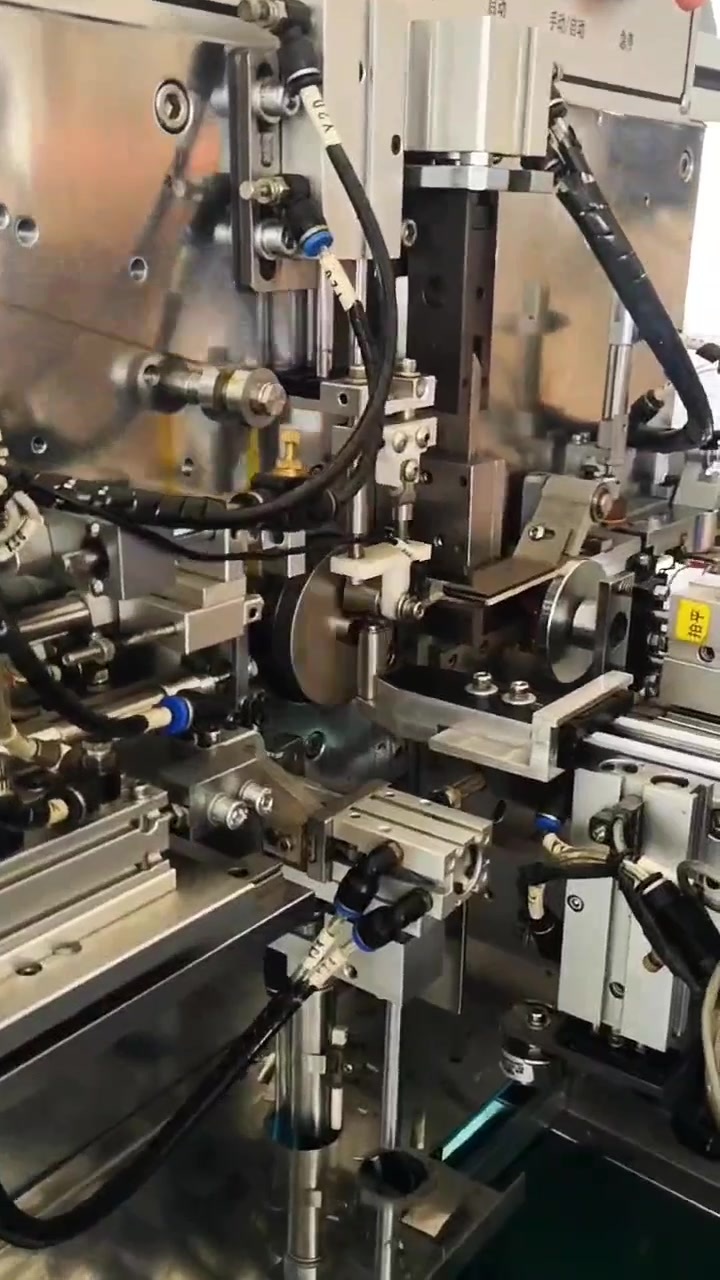

Semi-automatic laminating machine

This device is suitable for assembling the positive and negative electrodes of lithium-ion battery cells with isolation films in a Z-shaped stack. It automatically wraps the isolation film around the electrode group, cuts off the diaphragm, applies anti loosening tape, manually unloads, and collects the battery cells

Lamination Machine

positive

negative

diaphragm

electrode

polarizer

function

Classifications:

Lamination Machine

- Product Description

- Equipment Parameter

-

- Commodity name: Semi-automatic laminating machine

This device is suitable for assembling the positive and negative electrodes of lithium-ion battery cells with isolation films in a Z-shaped stack. It automatically wraps the isolation film around the electrode group, cuts off the diaphragm, applies anti loosening tape, manually unloads, and collects the battery cells

This device is suitable for assembling the positive and negative electrodes of lithium-ion battery cells with isolation films in a Z-shaped stack. It automatically wraps the isolation film around the electrode group, cuts off the diaphragm, applies anti loosening tape, manually unloads, and collects the battery cells.

Both positive and negative electrodes are configured as single material tanks, and the electrode plates in the tank have a real-time floating structure;

The use of slight bending, brushing, shaking action, and elastic suction cups can effectively prevent the phenomenon of sucking multiple pieces;

● Secondary precise positioning to ensure pole alignment;

The equipment is equipped with a dust removal device, which can collect the dust that falls off the polarizer in a centralized manner, ensuring the cleanliness of the mechanical table;

The positive and negative electrode pressure claws alternately press the positive and negative electrodes to prevent cross contamination;

Before stacking, the positive and negative electrode material slots are separated by partitions to prevent cross contamination;

Blow dry ion air onto the isolation membrane to remove static electricity from the membrane;

Secondary positioning installation of ultrasonic sensors, capable of detecting duplicate and missing pieces;

Adopting a servo driven laminating table can ensure uniform force distribution between each layer of polarizer;

Adopting imported seamless buffering suction cups, effectively preventing the occurrence of suction and indentation on the polarizer;

● It has diaphragm recovery function and first diaphragm correction function. -

Specifications and materials Materials Length Width Thickness um Intemal

diameterMaximum

outside diameterPositive Sheet material 65-190 25-100 100~280 – – Negative Sheet material 65-190 25-100 80~280 – – Positive ear – ≤30 10-50 – – – Negative ear – ≤30 10-50 8~20 – – Diaphragm Roll – 33-186 16~45 Φ76.2 Φ250

Video relacionado

Related Products

Fully automatic winding machine

Message to Us