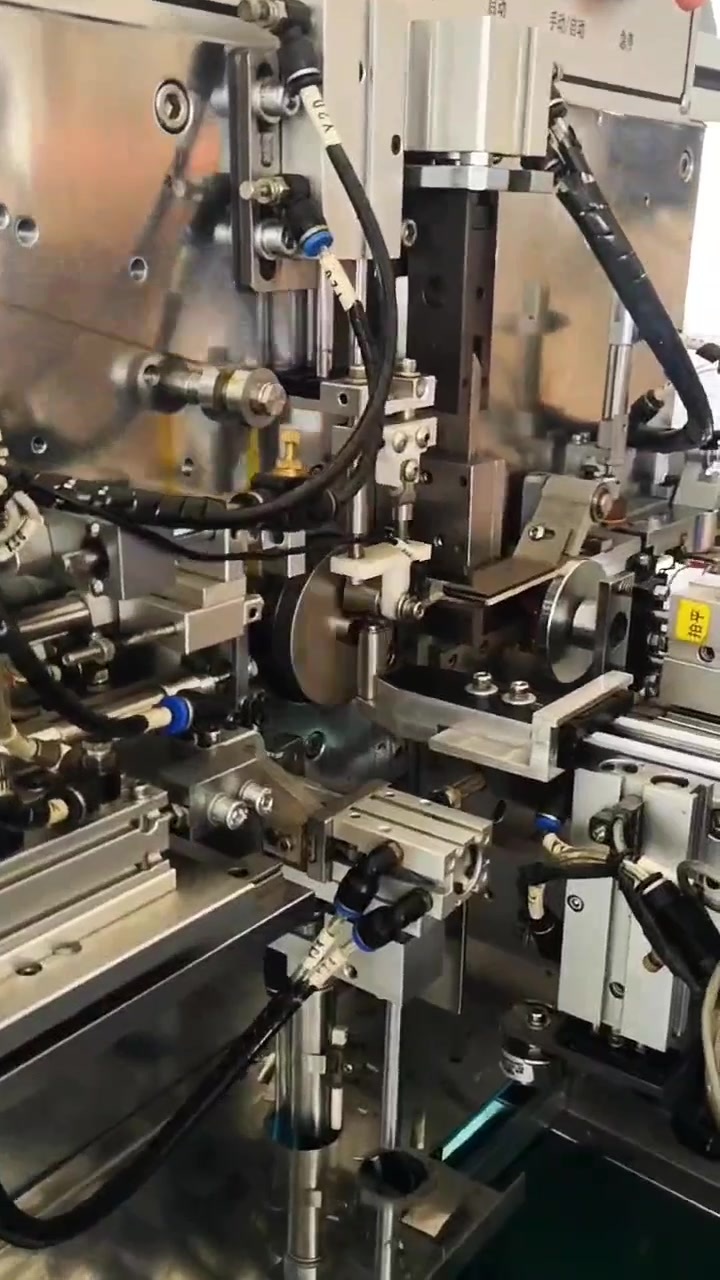

Precision grinding wheel cutting machine

Sealed high rigidity precision high-speed spindle

Silicon Steel Wafer Winding Machine

machine

cutting

Cutting machine

Classifications:

Silicon Steel Core Production Equipment In The Power Industry

Cutting Machines

- Product Description

- Equipment Parameter

-

- Commodity name: Precision grinding wheel cutting machine

Sealed high rigidity precision high-speed spindle

1. Sealed high rigidity precision high-speed spindle

2. Adopting synchronous pulley rotation to reduce vibration caused by rotation

3. Stepper motor+ball screw feeding, smooth feeding, small cutting marks

4. Braking device to reduce scratches caused by grinding wheel offset during tool retraction

5. Simplify cutting process, one person can operate multiple machines

6. Foldable hood design for easy cleaning and maintenance

7. Multi layer filtration system reduces the adhesion of grinding wheel chips and cutting, resulting in scratches on the cross-sectionScope of application Amorphous, ultrafine crystalline, nanocrystalline, film breaking composite, magnetic core, silicon steel, transformer, iron core, iron silicon aluminum, etc. (other types of materials can be customized) size 1600x1000x1800 mm Total Quality About 1000kg Total power 7.5kw Power Supply 380v 50/60HZ Operation method Tap button+Weinview touch screen operation mode Manual feeding and clamping → pneumatic clamping can also be used → automatic feeding and cutting → automatic tool retraction and stop after cutting is completed. The fixture can be customized according to the product using pneumatic or manual clamping Advanced waterproof grinding wheel motor Three phase asynchronous motor 5.5kw (can be selected according to customer requirements) Water pump Three phase 380V/250W Water tank capacity 120L Magnetic separator Three phase 380V/15W flow rate: 50L/min high-precision high-speed sealed spindle, spindle accuracy deviation and runout 0.003mm principal axis 0~5000r/min (adjustable speed, can display real-time speed) speed 300mm Cutting stroke 300mm (customizable according to requirements) Cutting size The maximum value is 400mm, and the inner diameters of 25.4mm and 32mm~100mm/s can be set according to product characteristics Grinding wheel specifications Feed rate 0~100mm/s can be set according to product characteristics -

Equipment model HY-350 Power type Motor driven Head movement form High rigidity rotary feed Cutting blade grinding wheel motor 380V三相50HZ/4KW Cutting wheel speed (R.P.M) 0~4000RPM variable frequency speed regulation+braking device Clamp type Manual Water pump 250W/380V Maximum central grip of vise (mm) According to cutting requirements Operation method PLC numerical control operation Outer diameter size of grinding wheel (mm) Below 350mm Inner diameter size of grinding wheel (mm) 3175MM shared 1 water tank (8L) Magnetic separator+three-phase sedimentation water tank Equipment size 1750*880*1600MM

Video relacionado

Related Products

Fully automatic winding machine

Message to Us