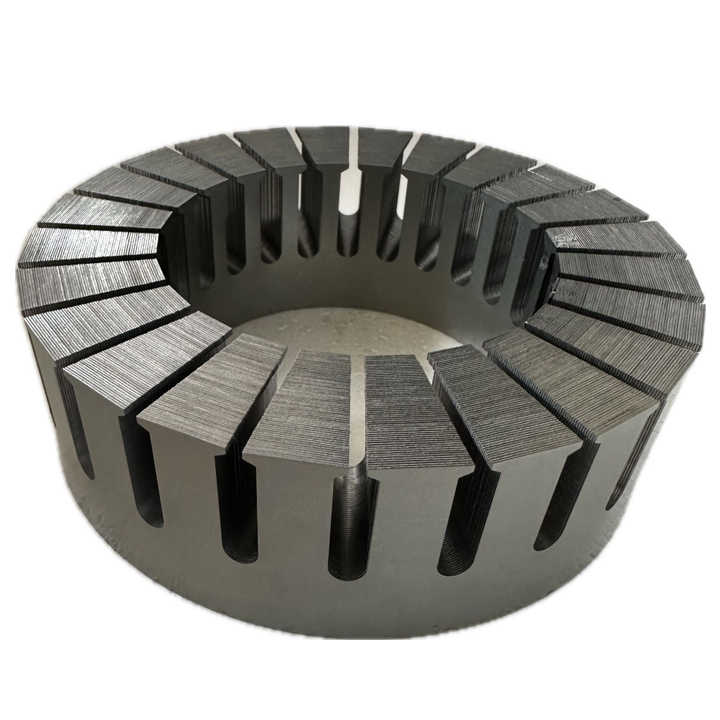

Disc type motor groove winding machine

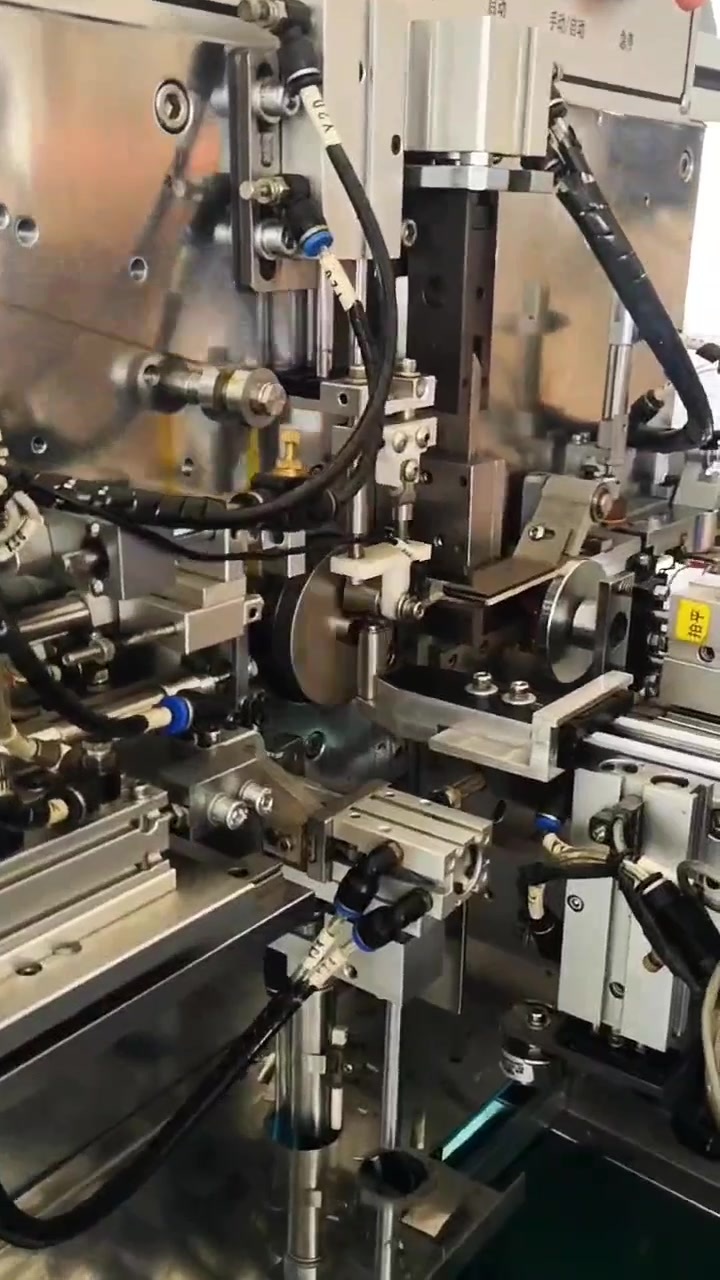

This machine is suitable for semi-automatic production of electronic iron cores for axial disc motors, including automatic feeding, winding, welding, and cutting processes.

Silicon Steel Wafer Winding Machine

winding

groove

punching

material

Winding machine

welding

mechanism

Classifications:

Silicon Steel Wafer Winding Machine

- Product Description

- Equipment Parameter

-

- Commodity name: Disc type motor groove winding machine

This machine is suitable for semi-automatic production of electronic iron cores for axial disc motors, including automatic feeding, winding, welding, and cutting processes.

This machine is suitable for the automatic production of axial disc motor electronic cores, and the process includes automatic feeding, winding, welding, and blanking.

◆ Discharging mechanism: manually put the strip, shrink the rack during installation, remove the front baffle, put the strip into the rack, expand the rack, and lock the nut. It is easy to operate and easy to install. The main power of the tray is driven by a three-phase asynchronous motor, which is controlled by a frequency converter, so that the discharge is accurate, stable and reliable.

◆ Orthosis: Through a plurality of rollers and multi-segment mechanisms, the strip is sent to the punching mechanism through the guide, and the surface of the wheel is smooth and does not damage the material, so as to ensure the stability of the product when winding. The roller is made of high-quality alloy, which is polished after chrome plating, with high hardness, good abrasiveness and long service life.

◆ Punching die: punching groove through high-speed servo punching mechanism, low noise, winding strip through this mechanism, controlled by the numerical control system servo motor, can adapt to different interval needs. Dynamically adjust the groove interval during winding, so that the uniformity of the punching hole is improved.

◆ Winding mechanism: The material belt is manually hung on the winding needle during winding, and the speed is dynamically adjusted during winding through servo motor control, so that the punching mouth is neat. The distance between the needle and the punching die is controlled by the screw rod, so that the winding diameter of the product is larger.

◆ Automatic welding: automatic internal welding and external welding. (Resistance Welding Machine)

◆ Winding mold: fixed reel is adopted, and automatic blanking is completed after winding.

-

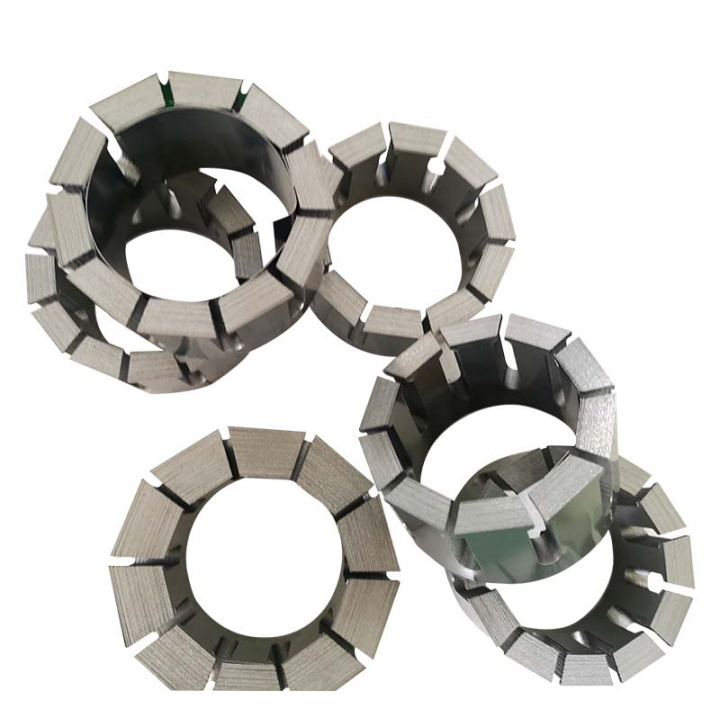

Parameters of automatic groove punching and winding machine for disc motor

Model HGC-250 HGC-350 HGC-450 HGC-550 Inner diameter of iron core mm 35~100 60-200 100-300 200~400 Core outer diameter mm 250 350 450 550 Strip width mm 25~50 30-60 40-80 50~100 Strip thickness mm 0.1~0.3 0.1~0.5 Belt winding and conveying speed 10mm/s~300mm/s (depending on the size of the inner and outer diameters of the product) Precision of iron core technology 1. After punching, the grain shape is neat and symmetrical, with a symmetry tolerance of less than≤0.25mm;

2. Burrs on the groove≤0.025mm;

3. Core stacking coefficient≥0.95;

4. The flatness of the iron core is less than ≤0.3mm;

5. Deviation of teeth size<1.5mm;

6. Bounce opening≤1.0mm;

7. The groove is straight, without any misaligned teeth, and the welding joint is firm and flat.Ordinary model Intelligent High functional type

Function Introduction

1. Manual feeding

2. Manual demolding

3. Punch press variable frequency motor

4. Manual welding

5. Sub arc welding machine1. Manual feeding

2. Bai Dong demolding

3. Automatic servo punching die

4. Automatic welding

5. Precision resistance welding machine1. Automatic feeding

2. Automatic servo punching die

3. Automatic demolding

4. Automatic cutting

5. Automatic welding

6. Laser welding machine

7. Automatic material discharge

Video relacionado

Related Products

Fully automatic winding machine

Message to Us