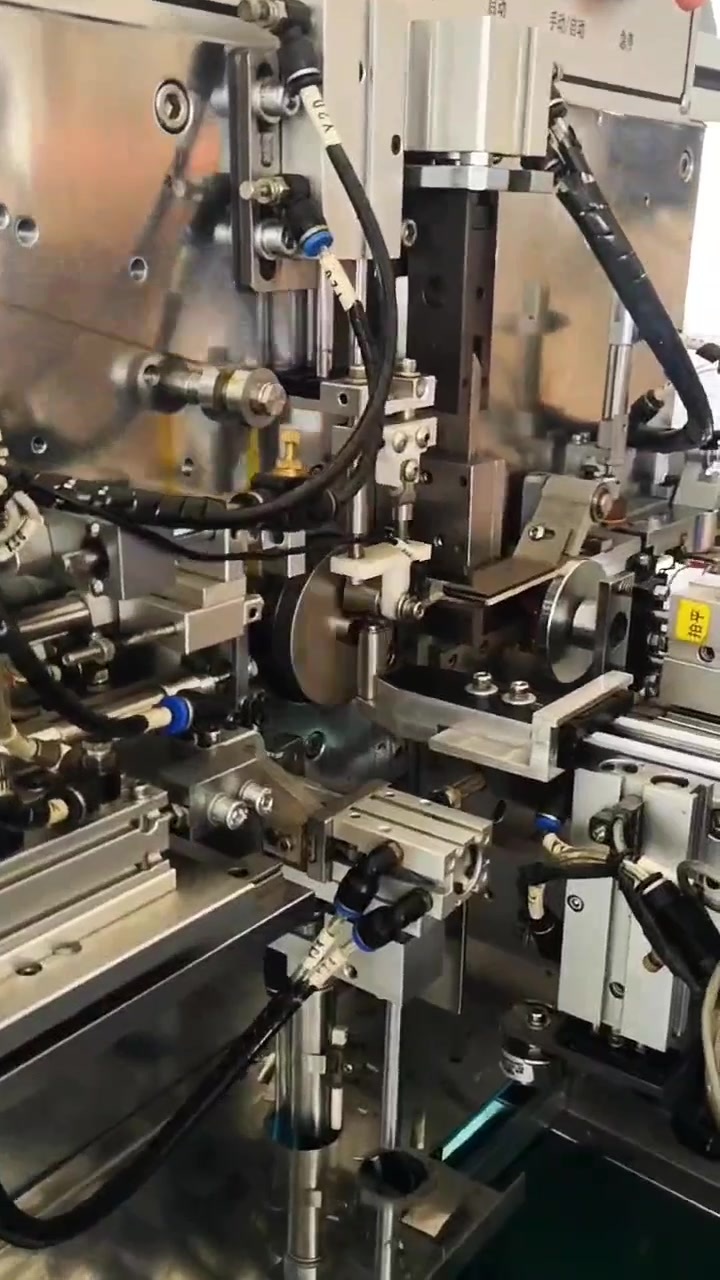

Medium sized amorphous magnetic core winding machine

The equipment is used for processing silicon steel strips, PO Mo alloy OD, CD, ED, (SD) type wound iron cores. During the processing, it automatically feeds on one side (the wound strip is intermittent in whole or loose coils; it can be fed in both directions), guides, winds, automatically calibrates, automatically cuts the head, and automatically welds the ends.

Winding machine

welding

tension

function

Classifications:

Amorphous Strip Winding Machines

- Product Description

- Equipment Parameter

-

- Commodity name: Medium sized amorphous magnetic core winding machine

The equipment is used for processing silicon steel strips, PO Mo alloy OD, CD, ED, (SD) type wound iron cores. During the processing, it automatically feeds on one side (the wound strip is intermittent in whole or loose coils; it can be fed in both directions), guides, winds, automatically calibrates, automatically cuts the head, and automatically welds the ends.

The equipment is used for processing silicon steel strips, PO Mo alloy OD, CD, ED, (SD) type wound iron cores. During the processing, it automatically feeds on one side (the wound strip is intermittent in whole or loose coils; it can be fed in both directions), guides, winds, automatically calibrates, automatically cuts the head, and automatically welds the ends.

The equipment operation adopts human-machine interface and PLC programmable control, with functions such as centralized display, accurate counting, photoelectric induction, and precise positioning; The spindle motor is driven by a synchronous belt; The counterweight adopts constant tension control, and the tension size display is adjustable; Equipped with a dedicated laser welding machine, it can set parameters suitable for welding materials of different thicknesses and grades;

The equipment should operate stably and reliably, and any abnormal operation or shortage of materials should automatically trigger an alarm and stop the machine; Its design and installation should comply with ergonomic and relevant safety regulations. -

Serial number

Project

Buyer demand parameters

Actual parameters of the seller

1 Winding speed (r/min) 0~100 (adjustable); 0~300 (adjustable); 2 Width of coiled tape (mm) 20~80; 20~100; 3 Thickness of coiled tape (mm) ≤0.35; 0.1~0.35; 4 Roll up product size (mm) Minimum rotating inner diameter of Ф50; Maximum rotating outer diameter of Ф300; Minimum rotating inner diameter Φ 50; Maximum rotating outer diameter is Φ350; 5 Maximum outer diameter of material discharge (mm) Ф400; Φ500; 6 Winding production efficiency (pcs/h) According to the processing of CD25x50x80 iron cores, ≥25 pieces; According to the processing of CD25X50x80 iron cores,>80 pieces; 7 Power (KW) — 10 8 Installation size (mm) — 2500x1600x1750 9 Winding core shaft Provide 5 sets (with dimensions that meet the demand) in accordance with item numbers 2 and 4. Provide 5 sets (with dimensions that meet the demand) in accordance with item numbers 2 and 4. 10 Winding method — Automatic core removal mold

Video relacionado

Related Products

Fully automatic winding machine

Message to Us